Sound deadening materials are essential across industries like automotive and construction to reduce noise levels and enhance acoustic comfort, with types including mass-based and resonance-based absorbers. Proper application requires understanding product properties, safety procedures, and hands-on training for accurate measurement, cutting, and adhesion. Simulated projects or real-world scenarios are crucial for practical experience, avoiding common mistakes like over-application, insufficient drying time, and misalignment to ensure effective sound deadening in complex car dent repair cases.

“Uncover the secrets behind effective sound deadening with our comprehensive guide. From understanding various material types and their unique applications to mastering the art of installation, this article is your ultimate resource. Learn about essential training components that ensure precise placement for optimal noise reduction. We’ll also shed light on common mistakes to avoid, empowering you to achieve professional results. Dive into the world of sound deadening materials and revolutionize your space.”

- Understanding Sound Deadening Materials: Types and Their Applications

- Essential Training Components for Effective Installation

- Hands-on Practice and Common Mistakes to Avoid

Understanding Sound Deadening Materials: Types and Their Applications

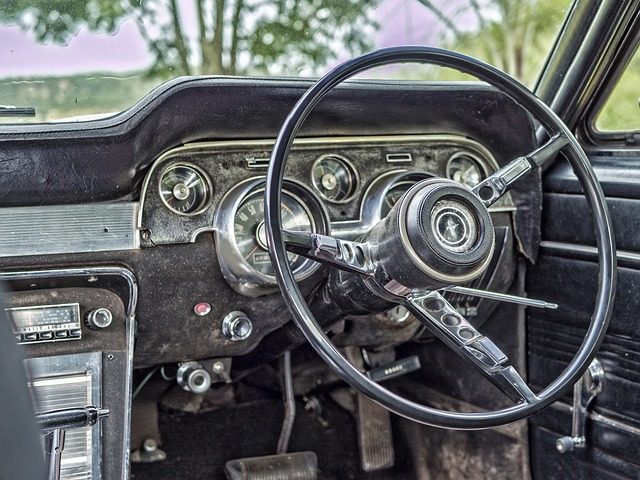

Sound deadening materials are an essential component in various industries, particularly in automotive and construction sectors. These materials are designed to absorb sound waves, thereby reducing noise levels and enhancing acoustic comfort. Understanding the types and applications of sound deadening materials is crucial for professionals involved in tire services, car body restoration, and vehicle repair.

There are different types of sound deadening materials available, each with unique properties and use cases. For instance, mass-based sound absorbers, like dense foams and mineral wool, are effective in absorbing low-frequency sounds. On the other hand, resonance-based absorbers, such as felt or fiberglass, target high-frequency noises. In vehicle applications, sound deadening materials are used to insulate interiors, minimize road noise, and improve overall passenger comfort. In car body restoration, these materials play a critical role in achieving that classic, silent ride while enhancing the structural integrity of the vehicle.

Essential Training Components for Effective Installation

When it comes to the proper application of sound deadening materials, essential training components are crucial for ensuring effective installation. These include understanding the unique properties and applications of various sound deadening products, such as their insulation values, weight, flexibility, and compatibility with different surfaces like metal, wood, or plastic. Proficiency in using hand tools, power equipment, and specialized applicators is also vital, as it enables technicians to accurately measure, cut, and adhere the materials according to specific vehicle designs and noise reduction requirements.

Additionally, training should cover safety procedures and best practices, including the use of personal protective equipment (PPE) to safeguard against harmful dust, fumes, or chemicals. Hands-on practice with mock installations, using sample panels or components similar to those found in vehicles, is indispensable for developing proficiency. This allows technicians to familiarize themselves with the techniques, tools, and materials needed for precise sound deadening application during auto body services, including vehicle dent repair and auto frame repair processes.

Hands-on Practice and Common Mistakes to Avoid

Practical, hands-on experience is invaluable when it comes to applying sound deadening materials effectively. After understanding the fundamentals through theoretical learning, trainees should engage in simulated projects or real-world scenarios to refine their skills. This step is crucial as it allows them to experiment with different techniques and materials without causing damage to actual vehicles, which can be costly in auto collision repair or fender repair scenarios. Common mistakes to avoid include over-applying materials, leading to unnecessary thickness and weight added to the vehicle; not allowing adequate drying time between layers, which can result in poor adhesion; and misaligning pieces, creating gaps that defeat the purpose of sound deadening.

By gaining experience through hands-on practice, trainees can learn how to navigate around tight spaces, ensure even coverage, and effectively seal joints and edges. This preparation is particularly important when dealing with intricate car dent repair cases where precise application of sound deadening materials can make a significant difference in the final aesthetic and acoustic outcome.

Proper application of sound deadening materials requires a combination of theoretical knowledge and practical skills. By understanding different types of sound deadening materials and their unique applications, along with undergoing comprehensive training that includes hands-on practice, individuals can ensure effective installation. Avoiding common mistakes is key to achieving optimal sound reduction results. With the right preparation, anyone can become proficient in using sound deadening materials to create quieter and more enjoyable spaces.